Balance problems and fault characteristics of rotating machinery

Published:

2019-05-20 14:09

Due to the unreasonable structural design, manufacture and installation error, the material is not uniform and non-uniform heating, and contact with other media and during the operation of the scale and corrosion or other reasons, such as the quality of all cross section rotating parts centers are usually not squarely on the axis line, rotating centrifugal force which will motivate the machine vibration, when vibration exceeds a certain standard, it caused the dynamic balancing problem we usually said.We can judge the size and position of the unbalanced mass on the rotating parts by vibration test and make correction, which is the dynamic balance.

Centrifugal force is proportional to the speed of the square, so in order to ensure safe operation, reasonable life and the surrounding environment will not produce serious vibration and noise pollution, usually on the high-speed rotating machinery dynamic balance requirements are very strict.

The causes of unbalanced faults usually include: mass imbalance, initial bending, rotor thermal imbalance, component scaling, shedding, coupling imbalance, etc. Although the causes of these problems are different, but the vibration characteristics are the same as the mass imbalance basis, so all imbalances can be attributed to the mass eccentricity of the rotor.

2.1. Rotor mass imbalance

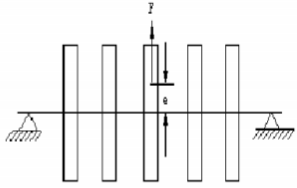

FIG. 1 shows the vibration of a multi-disk rotor with an eccentric mass.If the influence of gyro force is ignored, the forced vibration response formula of one degree of freedom can be used to calculate the steady-state response caused by the unbalance excitation force after the coupling is uncoupled using the modal coordinate counterrotating subsystem.

(figure 1)

According to the analysis, the vibration characteristics of rotor imbalance are:

(1) the center track of the disk is a circle or an ellipse.

(2) the steady-state vibration of each disk is a forced vibration with the same frequency as the rotational speed. Its amplitude changes with the rotational speed according to the resonance curve law in the vibration theory, and reaches the maximum value at the critical rotational speed.Therefore, the significant characteristic of rotor unbalance fault is that the amplitude of vibration of one frequency is large.

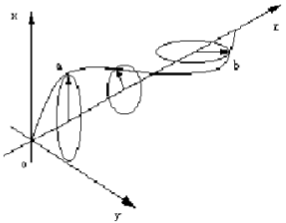

(3) the phase Angle of the complex number vector of the displacement of each disc center is different, so the axis is bent into a space curve, and the rotor speed is rotated around the oz axis, as shown in figure 2.

(figure 2)

(4) bearing vibration in different directions is not the same due to the influence of bearing stiffness in different directions, nonlinear oil film damping and nonlinear rotor and other factors.The horizontal stiffness is small, and the vibration amplitude is large, so that the entire spectrum is in the shape shown in figure 3.

(figure 3)

An unbalanced rotor causes vibration during rotation, which can be detected by sensors.The sensor can be installed on the stand to measure the vibration of the rotating shaft relative to the stand or the absolute vibration of the stand.Usually, a mark is made on the rotor, which is detected by a photoelectric sensor as a reference point for calculating the position of the unbalanced Angle.Because of bearing noise and ambient vibration, the signal measured by vibration sensor contains a lot of noise.However, it can be confirmed from the above analysis that only the part with the same frequency as the rotor is caused by rotor imbalance.By using the signal of photoelectric sensor and vibration sensor, the square wave or sine wave signal with the same frequency as the rotation speed can be obtained through the waveform transformation, and the size and position of the unbalanced mass can be determined accordingly, and then be corrected.

2.2 imbalance caused by other causes of the rotor

2.2.1. Initial bending of the rotor

Rotor initial bending and quality differences between the initial unbalance rotor initial bending is refers to the geometric center of the cross section of attachment do not overlap with rotation axis, the quality of the initial unbalance refers to the cross section of the center of mass and geometric center line of attachment is not coincidence, but both are eccentric rotor produce quality, so that the rotor unbalance vibration.

The initial torsion rotor and the mass initial unbalance rotor have similar vibration characteristics, but the difference is that the initial torsion rotor vibrates obviously at a low speed and tends to the initial bending value.

2.2.2. Rotor thermal imbalance

In steam turbine rotor as an example, in the process of starting and stopping of the unit, because of the difference of heat transfer rate, make the rotor cross section produces uneven temperature distribution, transient thermal bending in the rotor, create a large imbalance, hot bending caused by vibration, usually associated with load changing load, vibration change accordingly, but lags the change of load on time, with the stable operation of the unit, the whole machine uniform temperature gradually, gradually reduce vibration.

2.2.3 component shedding the main vibration feature of component shedding is that the vibration tends to be stable after a sudden change, and the vibration amplitude increases obviously.

2.2.4 scaling and corrosion of rotor parts

Since scaling and corrosion do not happen overnight, the vibration increases gradually with the passage of time, and the axial force changes due to the change of flow conditions, and the axial displacement increases and the efficiency decreases.

2.2.5 imbalance of coupling

Due to the manufacturing, installation deviation or dynamic balance when the impact of the coupling is not considered, so that the coupling is unbalanced, vibration characteristics are usually the coupling at both ends of the bearing vibration is large, the phase is basically the same.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.