Introduction of dynamic balancing machine

Published:

2019-05-20 14:40

The introduction of dynamic balancing machine today, the rapid development of science and technology and the refinement of equipment, especially for the heavy duty or high speed of the rotor of this spare part balance precision requirements are more and more high, the former soft balance is far from the balance accuracy of the rotor now.

2.1. Harm of rotor imbalance

We assume that a rotor carrying unbalance, it brought by the centrifugal force F= me 2 because some of the rotor field speed of 10,000 RPM, some large fan rotor also reached 1000 RPM.The radius is R and the centrifugal force is e.We can see that a rotor of 100 grams of unbalance centrifugal force is how big (some rotor unbalance has a few kilograms or more), it makes the rotor vibration, vibration affects the performance of equipment, so that the machine parts additional dynamic load, thereby shortening its service life;Vibrations often produce loud noises and pollute the environment.If the shaking reaches a certain level, the consequences will be more serious.2.2 set parameters and maintenance dimensions of the dynamic balancing machine: L W H=4.9 2 2.5 m;Balancing speed startup time <2 minutes;Speed range: 60-10000rpm;Rotor weight {1. Bearing support <25000Kg;2. Rolling support <20000 Kg};95% imbalance reduction;Power: 75KW.

2.2.1 the rotor rotating speed, and cut some weight is heavier, so every time we turn a car into the oil between the roller and shaft pouring, keep the each part of the lubrication system of oil is enough, oil flow, according to the provisions of the manual lubrication chart to choose lubricating oil, and keep the oil clean, keep the oil in the hydraulic system, pressure gauge clean, complete and in good condition.Pay attention to check abnormal noise and oil temperature is too high phenomenon.

The universal shaft coupling is oiled every two months. Before the frame is moved, the track is cleaned and the oil is poured. The balance speed selected each time should be slightly higher than the measured speed, so that the energy of the driving motor can achieve the best effect, but the speed cannot be too high, otherwise it will cause the prominent deformation of the rotor element.

2.3 composition and application of dynamic balancing machine

Dynamic balancing machine mainly has;Balancing machine track, two adjustable support, spindle box (dc motor, servo motor, spindle, dial and transmission mechanism), CNC control box composition.

The adjustable support pedestal mainly supports the balanced rotor, and the main components are two sensors.When the rotor rotates, the unbalance will cause vibration. When the rotor rotates at a certain speed, the vibration will also increase due to the increasing centrifugal force. At this time, the sensor starts to work.

After the rotor speed is stabilized in the balance, the sensor sends the electronic signal to the control box regularly. At this time, the CNC control box changes the electronic signal sent by the sensor into digital display on the display.

In balancing, due to the errors of personnel (locking errors of each link), the errors of the cardan shaft itself, the rollers and brackets, as well as the errors of the connecting flange, we must remove the unbalance of these errors in order to accurately balance the rotor.

2.4 compensation function of H60 dynamic balancing machine

H60 should support the dynamic balancing machine has a compensation function, is the rotor outside (the error of the cardan shaft and the rollers and brackets, as well as the connection flange error of the unbalance balance are compensated to cancel the function.

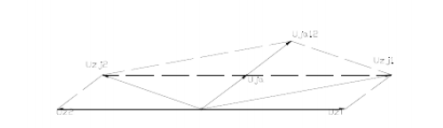

Principle as shown in figure: UZ1 and UZ2 is the rotor unbalance, U ja and Uja12 is fixture (vientiane shaft's own error, and the error of the connection block and lock the links (error) of unbalance), UZj2 and Uja12 (fixture) and rotor unbalance of the rotor turning computer with vector calculation method after 180 degrees Uja12 calculated out of UZj2 and UZj1 is we the unbalance of the rotor.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.