Rotating body dynamic balance

Published:

2019-05-21 15:42

1. Eliminate or reduce the dynamic pressure caused by inertial force or inertial couple by adjusting the mass distribution of rotary parts, so as to eliminate or reduce the periodic vibration of equipment;

2. Familiar with the basic method of rotor dynamic balancing and the working principle of industrial dynamic balancing machine.

3. Yyq-16, yyq-50 economic hard supporting dynamic balancing machine;

4. Yyw-5 universal joint balancing machine;

Principle and method of dynamic balance test

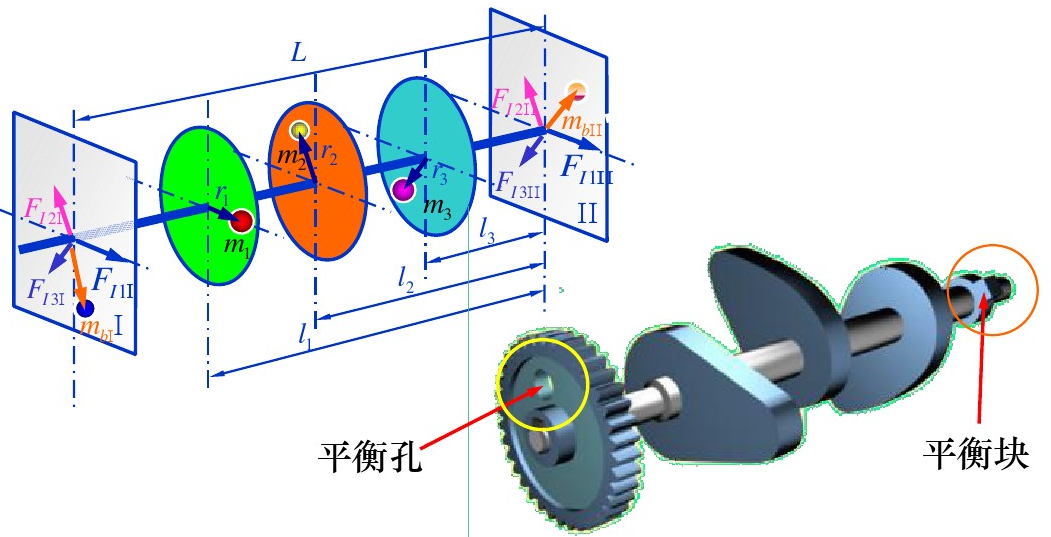

Rotary parts of the dynamic balancing machine, through the optional two correction plane to increase or reduce a certain amount of mass, so that the quality of the workpiece to re-distribution of the mass distribution of the center and the rotary axis coincidence, eliminate the unbalanced mass produced by centrifugal force and its couple.

The dynamic balance of the rotating body is completed on the dynamic balance test machine. There are many kinds of industrial dynamic balancing machines, but their composition and working principle are basically the same.

When the unbalanced workpiece is installed on the support and rotated, the workpiece and the support will generate vibration. The vibration signal is picked up by the sensor installed on the support and sent to the tester together with the reference signal generated by the reference signal generator.

The vibration signal generated by the sensor is a sinusoidal signal, and its amplitude reflects the magnitude of the unbalance that causes vibration.

The signal is processed and calculated by the tester, and the processing results are outputed-the size and position of the unbalance in the two correction planes.

The corresponding mass is removed or added in two calibration planes according to the test results, so that the mass of the workpiece is redistributed, so that the resultant centrifugal force and force couple generated by each mass are equal to or less than the allowable value, so that the workpiece reaches the dynamic balance.

Balance the instance

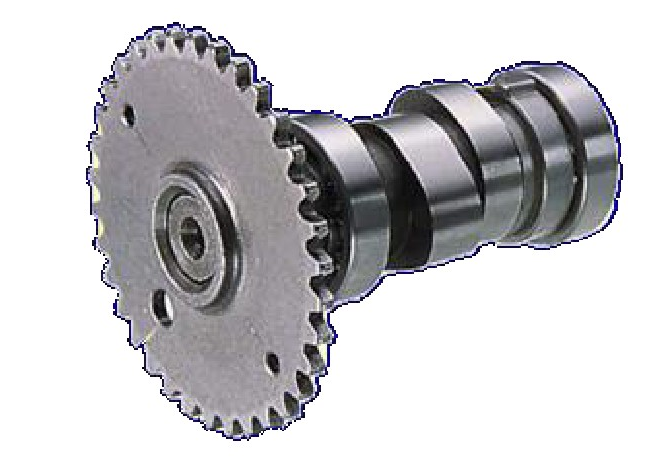

1. Install the rotor, and the belt winding method is shown in the figure;

2. After the power switch is switched on or the "exit" button is pressed, the measuring instrument enters the self-test process and everything is normal, the indicating panel will show Bal--20H

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.