What is a fully automatic balancing machine? Do you really use it correctly?

Published:

2019-11-18 13:46

The appearance of the balancing machine greatly facilitates the quality control of the dynamic balance when we produce the rotor. With our demand for the balancing machine, the balancing machine also has different styles. The fully automatic balancing machine is one of the mainstream styles. . The automatic balancing machine has many advantages compared with the traditional balancing machine, but many people do not know how to use the fully automatic balancing machine. Here is a description of the automatic balancing machine.

The fully automatic balancing machine pre-sets the whole process of the rotor correction (initial measurement-de-re-retest) to N programs, select one of the programs during rotor correction, turn on the power supply and start the balancer switch to complete the whole process of rotor correction. It will be done automatically.

The automatic balancing machine is calculated and matched with the de-weighting device to perform correction and re-testing by the initial unbalanced quantity: thus realizing automatic control.

The fully automatic balancing machines sold on the market today fall into three main categories:

Single station automatic drilling dynamic balancing machine

It is applied to all kinds of dynamic balance of motor rotor. After fully considering the balance accuracy of the whole assembly, the fully automatic series machine can eliminate the vibration caused by bearing and other components and assembly errors. The hard-supporting swing system expands the measurement range and reduces the failure rate. The clamp can be applied to the overall dynamic balance due to the use of a quick chuck fastening. The fast detection and calculation system, combined with the precise automatic de-weighting mechanism, can quickly complete the detection and de-duplication of the product.

Two-station automatic balancing machine

The feature of this balancing machine is that the correction time is short, the two stations are used together, and the work efficiency is high. Since the two stations are matched with each other, the correction rate is high, and the horizontal swing frame design is relatively simple to use. This balancing machine is suitable for rotor dynamic balance correction of small varieties and large quantities.

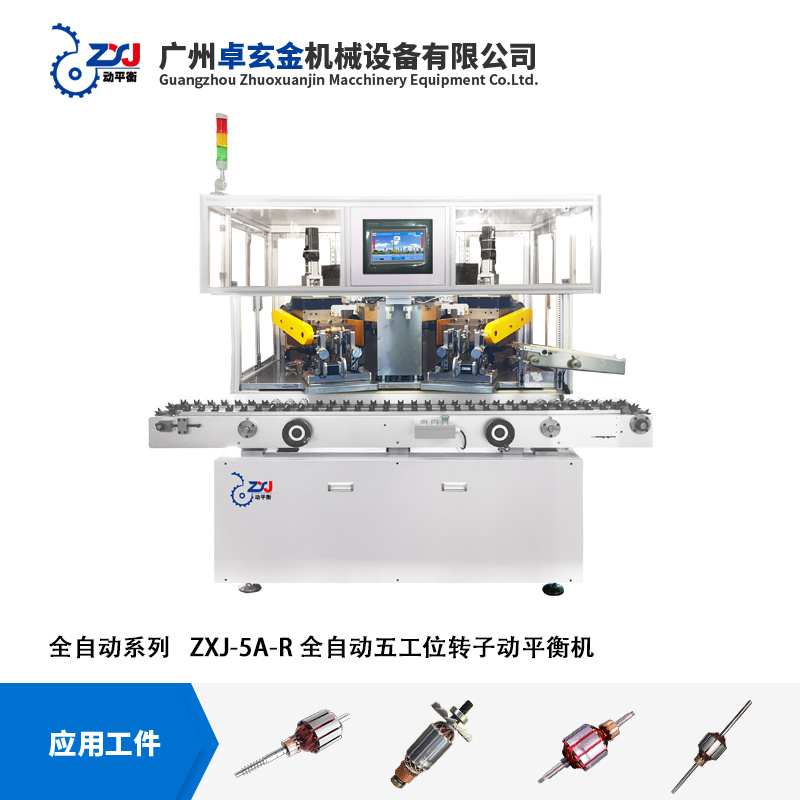

Five station automatic balancing machine

The feature of this balancing machine is that it can set up automatic production line production, and it can be used at the same time with five stations of the assembly line. The working efficiency is extremely high. Because it is matched with the production line, it is a horizontal swing frame design, which is relatively simple to use.

There are many brands of fully automatic balancing machines that are commonly available on the market, and there are many options. You can choose the right balancing machine according to the required functions and correcting the workpiece.

For me, an electric idiot who can't find a TV search switch, the automatic balancing machine means that after reading the manual several times, I can only choose to contact the customer service sister silently, and teach me step by step. The method, um, is a deep impression that you should never forget to forget.

Step analysis:

1. The operator places the new rotor into the measuring station and presses the start button.

2. Wait for the rotor processing on each station to be completed.

3. The manipulator also carries the rotor on the measuring station to the cutting de-duty station for the correction of the unbalance amount.

4. Transfer the rotor that has completed the initial calibration from the cutting de-duty station to the measuring station for re-testing:

5. At this time, if the rotor on the measuring station is qualified, continue with step 1. If not, continue with step 2.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.