Introduction of dynamic balancing machine measurement system

Published:

2020-02-27 11:06

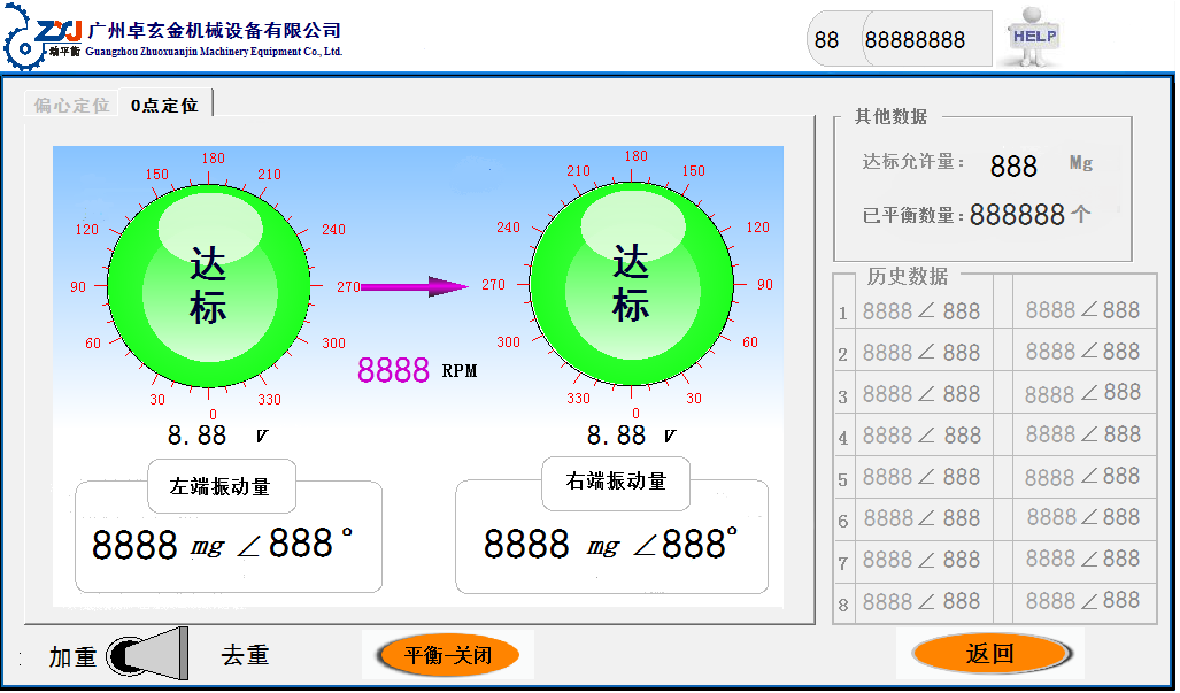

The dynamic balance machine measurement system is a system that can monitor and locate the unbalanced amount of the measurement workpiece. The user can know the balanced state and unbalanced position of the measured workpiece in real time from the system interface, and can also automatically or manually calibrate the workpiece. According to the actual needs of the user, there are also functions such as fault alarm of the dynamic balancing machine and preset stop of unbalanced position.

The biggest advantage of the dynamic balancing machine system is high-sensitivity sensing and calculation. With the help of sensing equipment, it can accurately calculate the measurement of the unbalance data of the workpiece and reduce the measurement error. In the production line system with high-precision balancing requirements, the dynamic balancing machine mainly performs operations such as quality monitoring and quality improvement of measured workpieces, can save hundreds of workpiece specifications, and fully adapts to long working hours, large workpieces, and high requirements for workpiece balance accuracy Demanding technical requirements.

In order to maintain the stable operation of the dynamic balance machine system, it is very important to control the system. The measurement system of the dynamic balance machine is required to operate the entire system measurement, calibration selection and other operations. Due to the differences in workpieces and weights, and the special support design of the dynamic balance machine, the current computer hardware of the dynamic balance machine measurement system mostly uses embedded industrial computer products. At present, the advanced intelligent dynamic balancing machine of Zhuo Xuanjin dynamic balancing machine adopts Japanese, German and other dynamic balancing machine technologies. After years of domestic exploration and testing, it now has excellent practicality and rich application. High-precision measurement, human-computer interaction friendliness, intelligence, and easy integration have become the technical representatives of Zhuo Xuanjin's dynamic balancing machine. The dynamic balance machine measurement system has the functions of multiple groups of data display and operation prompts.

This article is provided by Guangzhou Zhuoxuanjin Machinery Equipment Co., Ltd. The company specializes in the design, development and sales of automatic balancing machines, automatic positioning dynamic balancing machines, self-driven full-automatic balancing machines, loop-driven balancing machines, universal joint balancing machines, Horizontal dynamic balance machine, vertical dynamic balance machine, on-site dynamic balance instrument, etc., you can also develop various types of dynamic balance machine according to your requirements.

You can also contact our online customer service (qq: 3233915463 // phone: 18933956581 // landline: 020-36969823) We will serve you wholeheartedly and look forward to your contact.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.