High-precision measurement system-analysis of advantages and disadvantages of automatic positioning dynamic balancing machine

Published:

2020-05-18 10:23

There are several measurement systems currently used in the field of dynamic balancing machines. Today Zhuo Xuanjin will introduce the advantages and disadvantages of automatic positioning dynamic balancing machines, and comparison with other measurement systems.

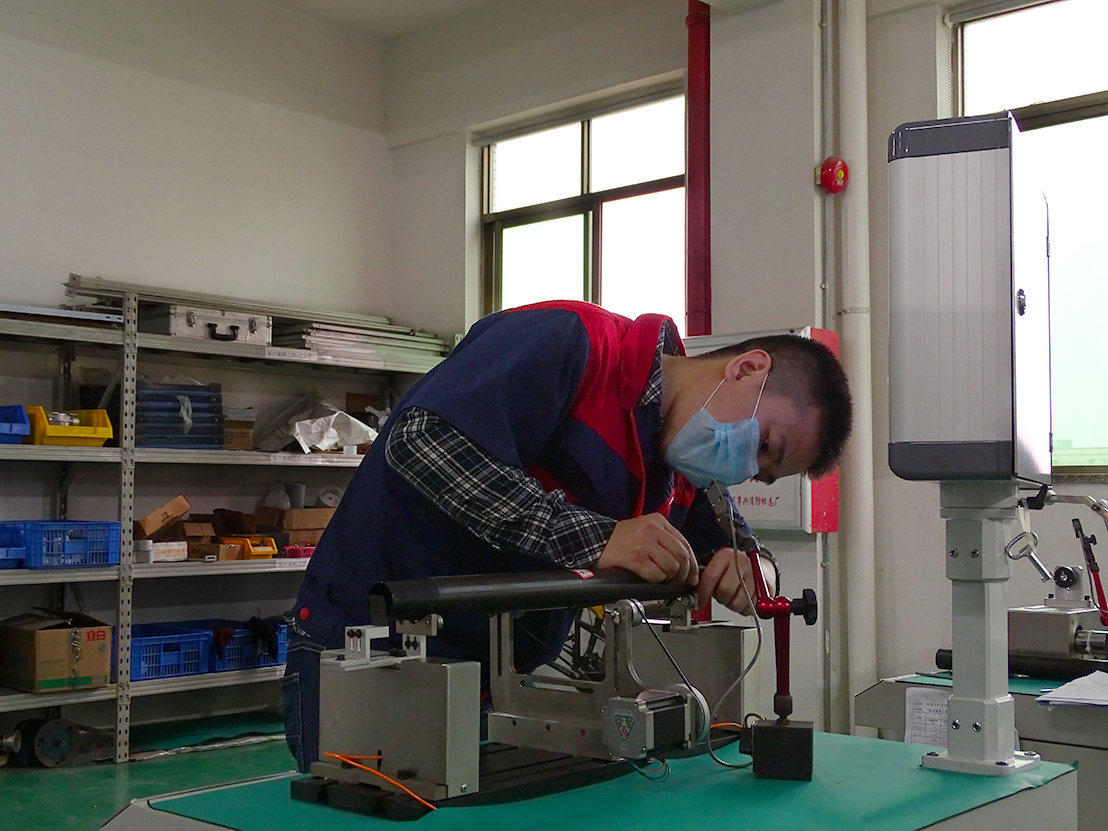

(Treadmill roller dynamic balancing machine)

The automatic positioning dynamic balancing machine is an autonomous measurement system that does not require marking and can accurately stop the angle at which the rotor unbalance is measured to a specified position. The automatic positioning dynamic balance machine is a sensor system that measures the acceleration rotation of the rotor in the transmission system, and then automatically collects data to obtain data such as the unbalanced centrifugal force and position of the measured rotor, and transmits it to the measurement system to obtain Measure the rotation speed of the rotor and the size and angle of the unbalance.

The advantage of the automatic positioning dynamic balancing machine is that after the initial conditions are given, the angle of the rotor unbalance amount can be stopped at the specified position without the operator looking for the unbalance amount position, the measurement accuracy is high, and the measurement time is only 3 to 5 seconds. It is suitable for the accurate measurement of various rotors with high balance accuracy requirements, and can independently stop the unbalance at the specified position and reduce the speed to correct the error.

With the increasing demand for high technology in the economy today, people's understanding of the technology of automatic positioning dynamic balancing machines is continuously popularized and deepened. The application field of automatic positioning dynamic balancing machines has been expanded from laboratories to civilian use, and efforts are being made to develop market competition Powerful new technologies and products.

The brushless motor is a key accessory for UAV production. Due to the rapid development of the brushless motor industry, the automatic positioning dynamic balancing machine has also played a role in boosting the development of the brushless motor industry. At the same time, due to the increasing urgency of miniaturization and high performance of brushless motors, the high demand for balance precision, etc., high requirements are placed on the technology and quality of brushless motor production, as well as efficient and precise dynamic balance accuracy. High demand.

When measuring and calibrating when the rotor is dynamically balanced, it takes a long time and requires a large cost. In order to reduce costs and improve efficiency, the use of intelligent measurement technology is imperative. Therefore, the development of automatic positioning dynamic balancing machines is receiving more and more attention. Among the many measurement technologies, the dynamic balancing machine with its unique advantages has become the best solution for rotor dynamic balance correction.

Therefore, the use of dynamic balancing machines is becoming more and more common. The application of automatic positioning dynamic balancing machines realizes the intelligent measurement of rotor dynamic balance, which greatly improves the efficiency of dynamic balance correction and reduces the correction errors.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.