Measurement composition and common problems of the ring driven balancing machine

Published:

2020-05-20 11:37

Ring driven balancing machines are widely used in motor rotors, transmission shafts, crankshafts and other products, which have direct or indirect impetus to reduce labor costs, reduce labor intensity, increase intelligence, improve production safety and improve product quality. Driven by the policies of intelligent manufacturing, the ring-driven balancing machine has been widely used in various industries such as automobile manufacturing, aeromodelling, household appliances, and power tools. This article mainly introduces the composition and common problems of the ring-driven balancing machine, so that everyone can understand more about the ring-driven balancing machine.

1. The composition of the ring-driven balancing machine

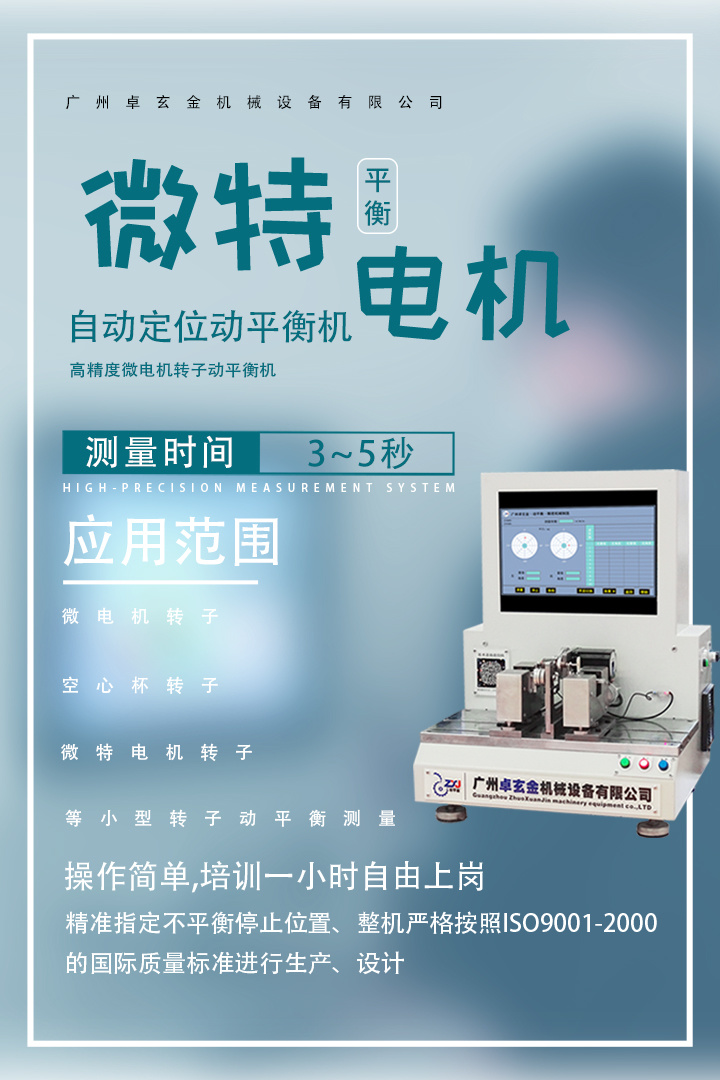

The ring-driven balancing machine is composed of a driving system, a sensing system and a measuring system.

(1) Drive system

The drive system of Zhuoxuanjin dynamic balancing machine can be divided into horizontal double-support drive, horizontal single-support drive, single-side vertical drive, double-sided vertical drive, whole machine self-drive, etc .;

(2) Sensing system

Dynamic balance machine sensor system mainly collects centrifugal force data generated during rotor measurement. When the sensor system receives the signal to measure the centrifugal force generated when the rotor rotates, it will convert the data and transfer it to the dynamic balance machine for measurement. The dynamic balance machine measurement system uses the data calculation to prompt the centrifugal force on the measurement interface.

(3) Measuring system

The measuring system of the ring-driven balancing machine is mainly composed of software such as dynamic balancing machine management monitoring, dynamic balancing machine management software module, and integrated wiring. When the sensor system transmits data to the measurement system, it will analyze, calculate, etc. the data, and control the transmission system to stop the measurement rotor unbalance at the specified position.

Circle driving balance machine display value error and countermeasures

1. First check whether the rotor being balanced itself is qualified.

Such failures are more common in the maintenance industry. For example, a car transmission shaft may have a bent shaft itself, the gap of the universal joint is too large, the gap of the spline shaft is too large, or the spring of the flange fork joint is loose, resulting in a universal joint These problems can cause large balance errors. When encountering a curved drive shaft, you can first use a straightener to straighten it, and then balance it: the movement of the universal joint of the flange fork link causes the balanced rotor to reverse 180 °, causing a new imbalance At this time, the spring leaf must be pressed well. Or thinner copper skin to fasten. The gap of the universal joint is large and can be replaced. The spline shaft can be repaired. If it still cannot be balanced, only the new drive shaft can be replaced. This is a typical case. Other shafts may also have problems caused by various processing and assembly. The same failures mentioned above must be checked first.

2. Is the balance speed stable?

The dynamic balance machine generally uses the speed signal as a reference signal to send to the measurement system. If the speed is unstable, the reference signal is also unstable, and it is also unstable after processing by the microcomputer, and the error is large. In this case, it is necessary to check whether the conveyor belt of the motor pulley is too loose: the belt-driven rotor, its belt slips. If the above situation occurs, you need to fasten or replace the belt. In addition, you can use a speedometer to check the speed of the motor itself.

3. The transmission of the sensor.

The sensor of the dynamic balancing machine is the most sensitive part in the dynamic balancing machine. If the sensor has no output or the output is unstable, it will cause balance errors. A high-sensitivity multimeter can be used on site to check whether both sensors have output signals. Watch the signal changes carefully. If there is no output signal, check whether there is a short line inside the sensor. If it is a magnetoelectric sensor, it also depends on whether the sensor connecting rod is bent to cause blockage, etc. . If there is a signal, but it is unstable, you should carefully check whether the sensor is loose or there is a short circuit between the coil turns. If it is a piezoelectric sensor, you can tighten and adjust the screws on both ends of the piezoelectric sensor. If it still does not work, you have to replace the sensor.

4. Recalibration

Generally, the measurement system of the dynamic balance machine has a storage function for storing different types of rotors. Sometimes, due to the aging of the electrical measurement system components or due to temperature, the parameters of a certain type of rotor are changed, resulting in errors in calibration. The rotor can be calibrated again.

With the development of the dynamic balancing machine and the improvement and progress of the technical level, the adaptability and measurement accuracy of the dynamic balancing machine have been greatly improved. Zhuoxuanjin dynamic balancing machine has become a key device for intelligent high-precision measurement of rotors. It is widely used in today's smart industrial production field and is a key element of the next generation of smart manufacturing.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.