Examples of rotor imbalance fault diagnosis

Published:

2019-06-03 10:38

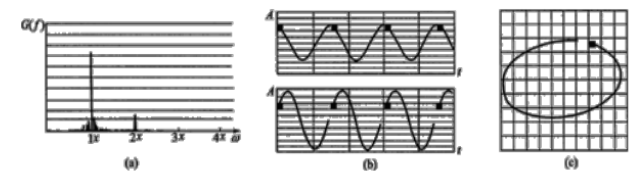

Example 1: the steam turbine of a large centrifugal compressor set started up with strong vibration after the rotor was replaced.The radial amplitude of the bearings at both ends of the compressor reaches the alarm value, and the machine cannot run normally.The main vibration characteristics are shown in figure 1-1.

FIG. 1-1 vibration characteristics of compressor

As can be seen from the figure: (1) the vibration size with the change of rotation speed rise and fall obvious (2) time domain waveform for sinusoidal wave;(3) axis trajectory for the ellipse;(4) vibration phase stability, is synchronous positive precession;(5) the energy concentration in the spectrum is 1× frequency, there is a prominent peak, the higher harmonic component is small.

Diagnosis opinion: according to the above vibration characteristics, it can be seen from the "characteristics of unbalanced fault" that the strong vibration of the compressor is caused by the rotor imbalance.

Check the inventory record of the rotor, the inventory time is long, because the rotor is heavy, the custodian did not cycle rotation according to the provisions, the preliminary conclusion is that the rotor dynamic balance caused by bad.

Treatment measures: the unit fault is caused by rotor imbalance, will not rapidly deteriorate in the short term.Considering that the chemical production process can not be interrupted, the study decided to monitor the operation.

Production verification: under the premise of strengthening monitoring, the vibration trend is stable, without increasing trend.

Maintain the operation of an overhaul cycle (18 months), the next overhaul when the replacement of the rotor and sent to the professional factory inspection, found that the dynamic balance seriously exceed the standard.

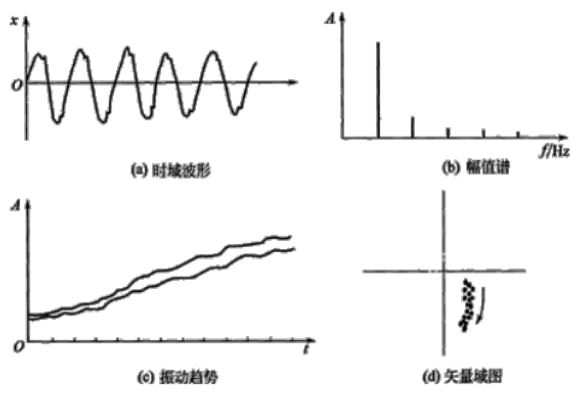

Example 2: the vibration value of the low-pressure cylinder rotor of CO2 compressor unit of a certain 520,000 tons/year urea plant is normal after overhaul, but the on-line monitoring system finds that the vibration value has a trend of gradually increasing.Its time domain waveform is sinusoidal wave, analysis of its spectrum, mainly 1× frequency, analysis of its vector domain graph, there is a slow change in phase.See figure 1-2.FIG. 1-2 vibration characteristics of gradual unbalance of co 2 compressor

FIG. 1-2 vibration characteristics of gradual unbalance of co 2 compressor

Diagnostic opinion: after two months of continuous observation, according to its vibration characteristics and the screening methods of several kinds of unbalanced faults described in this section, the fault reason is judged to be gradual unbalance, which is caused by the rotor runner scaling or local corrosion.

Treatment measures: the gradual change imbalance will not deteriorate rapidly in the short term, and once the normal production is interrupted, it will lead to huge economic losses. Therefore, we decide to monitor its operation with the online monitoring system, and deal with it after the overhaul.

Production verification: annual overhaul of the factory 6 months later, check in the machine repair workshop after replacement of the rotor, the rotor is not bent;The result of visual inspection shows no scaling and corrosion.However, after the professional factory was sent for dismantling inspection, it was found that the inner side of a shaft sleeve (the part cannot be seen when the rotor is not removed) had local serious corrosion, which led to the gradual increase of rotor imbalance quality.

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.