Dynamic balance in the assembly of fan impeller

Published:

2019-06-03 14:29

We theoretically discussed the impeller dynamic balance state, is in the manufacturing of impeller material (material is uniform, continuous, to homogeneity which do not contain impurities), process (stamping, spraying, riveting, assembly), shape tolerance (hole of the motor shaft, impeller, the impeller blade machining size), and so on are ideal conditions for;However, it is impossible to achieve this in the actual situation. There is a certain error between the actual state of the impeller and the ideal state.For example, the author has observed that some of the treatment of poor impeller blade surface coating flow phenomenon, which should have a certain impact on the dynamic balance of the impeller.

In the process of installing impeller for the range hood, whether the dynamic balance characteristics of the impeller can be maintained depends on the following factors:

1 detection factors

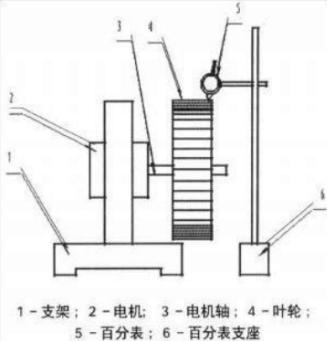

The detection equipment of impeller dynamic balance is relatively expensive, and the detection method is relatively complex. In many manufacturers of the whole oil absorption hood, there is no technical means for strict detection of the impeller. Generally, some relatively simple methods can only be used for detection, such as the use of percentage meter for detection (see figure 1).

FIG. 1 using dial indicator to detect the balance state of impeller (it is simpler to choose dynamic balancing machine)

As you can see, using the dial indicator to detect the state of dynamic balance of the impeller, can only get a general impression, because in this way can only on the impeller of the radial and axial (face) beating an approximation, impossible to get more accurate data, so only the impeller have a general understanding of the dynamic balance of drift;In addition, this detection method is actually a static balance mode rather than a dynamic balance mode. The obtained data only have reference significance for the position of the center of mass of the impeller in the state of high-speed rotation.

2. Test the benchmark factors

When using a dial indicator to measure impeller, USES a common motor shaft instead of using special sample axis to test for the benchmark, as a result of the ordinary motor shaft tolerance not been inspected, so between the testing results of the impeller and design intent may form a larger error, so the impeller dynamic balance characteristics of values between the impeller design intent and have a was there should be no error so this look reliable detection method, are not reliable.

Installation tolerance factor

In the process of installing the impeller, the tolerance distribution between the shaft of the motor and the hole of the impeller is not considered

Is to advance through detection and combination, with smaller error tolerance motor and impeller installed together, but for motor and impeller assembly work at random, so it will be difficult to avoid the motor shaft and hole of the impeller has greater tolerance, will be in the motor shaft and impeller combination of parts appear larger gap, impeller dynamic balance will also be affected (see figure 2).

FIG. 2 shows the influence of the hole tolerance of the shaft impeller of the motor on the dynamic balance state of the impeller

Related news

2018-12-03

In addition, if you need to buy a balance test machine, please contact us directly.

2018-12-03

Safety operation of the rotor of the motor to be balanced

电机转子装配工的一般操作规程如下: 1、工作前,整理场地,放稳各零、部件,并检查装配使用工具和工作环境是否安全良好。 2、吊放电机机座、底板、定子、转子、轴承等大型部件时必须放好方箱或垫木...

2018-12-03

Rubber roller dynamic balancing machine customer site

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances

2018-12-03

Mainly used in micro-motor rotors, such as automotive motors, household electrical appliances, micro-motors

2018-12-03

[Guangzhou Zhuo Xuanjin] balance machine application range

Dynamic balancing machines are widely used and can be divided into ten categories

2018-12-03

Guangzhou Zhuo Xuanjin various balance machines and their application range

Mainly used in the balance correction of high-speed rotating workpieces in various household appliances, cooling fans, motors, generators, pumps, automobiles, printing, rollers and other industries.