PRODUCTS

CONTACT

Guangzhou Zhuoxuanjin Machinert Equipment co.Ltd

Fax:020-36969822

Add:No. 34, Dahua Street, Huadu District, Guangzhou, Guangdong

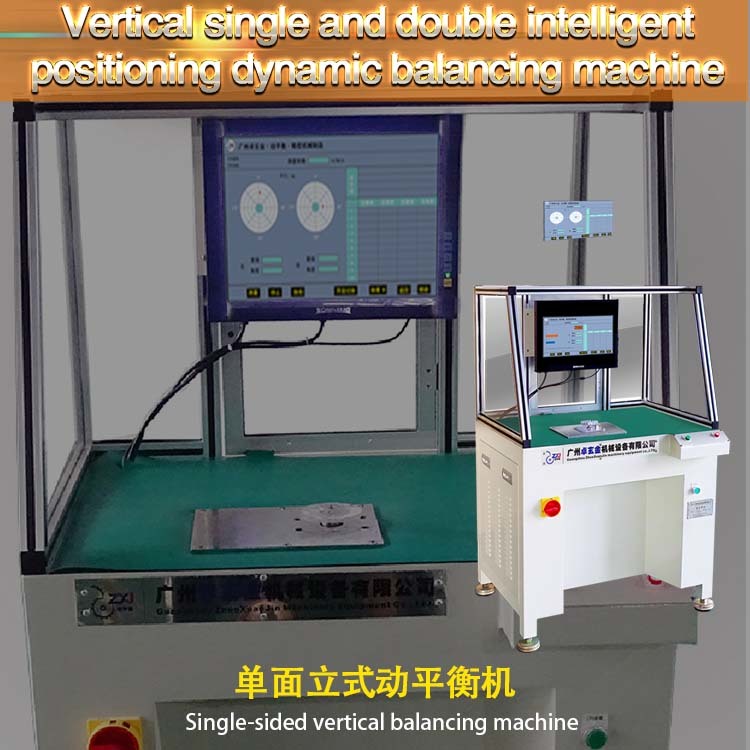

YD-0.5DW Vertical dynamic balancing machine automatic positioning single-sided balancing machine

YD-0.5DW Vertical dynamic balancing machine automatic positioning single-sided balancing machine

key word:

- Description

- Image display

- Product parameters

- Customer site

- Troubleshooting

-

No need to mark the measurement, can achieve high

precision positioning

Automatic tracking groove technology will not cause

positioning error due to belt slip

WindowsEnglish measurement software, can log in 100

specifications, a calibration call at any time

No need to stick reflective mark, USB data export, N kinds

of data storage, flexible location

Touch screen display, touch - on, simple and beautiful

Weighting/deweighting can be switched at will and is

easy to use

The equipment is equipped with automatic diagnosis

function and easy maintenance

Set many advantages in one, only to give customers the perfect dynamic balance detection, so that customers feel more at ease

Automatic marking system (optional) can also display left

and right positioning Angle difference

Product Feature

Keep Improving Pursue Perfection

Technical Parameters

Structure Parameter

65cm

45cm

Vulnerable

artifacts:

Because of professional, so trust

Essential InformationProduct Paramete

Φ50

Gauge

And the number

Workpiece quality

range(kg)

0.25

Maximum outside diam

eter of workpiece(mm)

Φ130

Workpiece height

(mm)

Unbalanced

reduction rate(%)

90

Spindle speed (r/min)

Minimum reachable res

idual unbalance (E mar)

1000/3000

≦0.2g.mm/kg

Power supply

equipment

AC220V50-60HZ

500VA

One year warranty for mechanical parts, one year warranty for

electrical parts, one year warranty for electronic components

Replacement of all kinds of idle old, old and residual dynamic balancing

machine equipment purchased by the enterprise in the early stage,

replacement scheme is determined according to the actual field

investigation results;

The prophase purchase of zhuoxuanjin dynamic balancing machine

equipment due to idle, and there are new products need to re-purchase

dynamic balancing machine, can consider the way of exchange

cooperation;

Home delivery, free arrangements for personnel home transfer

and training guidance;

Professional after-sales staff 24 hours telephone video voice

guidance sudden operation change and forget to operate and

other problems

Equipment lifetime maintenance, wearing parts to provide

lasting, so that the use of equipment more assured

The workpiece speed range is in:1000-3500 3500-8500

8500-30000

Production demand: large variety quantity, small variety

quantity and small variety quantity;

Product industry, varieties, specifications, weight, shape, size;

Balance

correction:

Feeding (adding mud, clamping, ring,welding,... )

Cutting (cutting, drilling, milling, grinding,planing,

scraping,... )

Balance levels range fromG40、G16、G6.3、G2.5、G1、G0.4

The initial measurement is qualified and the number of thick

grooves in the outer diameter of the rotor is measured

Member's Rights

1、Date Of Delivery

Normal production period is 6 working days (can be booked in advance)

2、Payment Method

Down payment deposit to arrange production

3、Quality Criterion

1.Product manufacturing standardGB4201-2006/ISO2953:1999

2.The product manufacturing requirements shall be strictly in accordancewith the technical requirements determined by both parties

4、Guarantee Period

The "three guarantees" period of party b's products shall be one year, and

after-sales service shall still be provided one year later.

5、Product Acceptance

1.Check and accept the equipment in the supplier's workshop. Check and verify

the rotor test.

2.The equipment shall be inspected and accepted by the user on site. The inspectionshall be carried out in accordance with the technologies determined by both parties

in the early stage, and the basic operation training shall be completed.

6、After-Sales Service

1.The supplier is responsible for providing training services for the equipment ordered bythe

purchaser, such as operation balance calculation and troubleshooting.

2.In case of equipment failure, the company will support the response in the fastest way afterreceiving the notification from the user.The arrival time shall not exceed 48 hours, andthe

maintenance work shall be carried out (after that. If the equipment is in the period of three

guarantees, only the transportation fee for the personnel shall be charged, and the travel

expense for the personnel shall be charged, and the cost fee for the replacement of the

accessories shall be charged).

3.The company is responsible for the maintenance of equipment after three packagesandprovide spare parts supply services.

-

Related products

Get product quotes for free